top of page

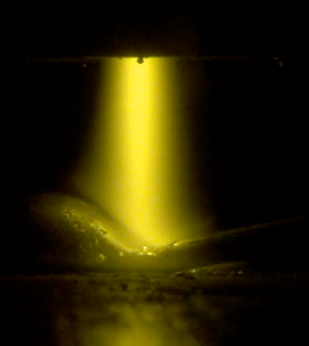

Additive Design and Manufacturing Systems Lab

Innovate. Collaborate. Advance.

Research Focus

We work towards advancing engineering design and manufacturing process productivity through discovery, research, and development of next generation processes, systems, and materials for the industries of future.

Gallery

Contact

bottom of page